It’s Not Magic, It’s Our Technology.

Our patented micromilling technology transforms real sugar, salt, and spices into flavor-boosting powerhouses – cutting the junk, not the joy.

Where Food Gets an Upgrade.

O’Taste is a flavor-delivery technology company focused on increasing the efficiency and impact of real food ingredients.

Through our patented wet micromilling and oil-suspension platform, we increase the surface-area exposure and optimize the behavior of real ingredients, enabling significantly stronger flavor release, reduced ingredient usage, improved sensory performance, and clean-label reductions — all while supporting scalable industrial use.

We provide ingredient behavior optimization, not artificial substitutes or flavor additives.

How It Works

Big Taste, Tiny Particles

Ingredients are reduced to the micro-scale (~5 μm), dispersed in any oil, and optimized for improved flavor availability and predictable sensory performance.

O’Taste’s oil-suspended flavor systems are designed for seamless integration across standard manufacturing lines. From spraying, tumbling, and baking-in to enrobing, folding, and post-fry application, our solutions ensure consistent, concentrated flavor delivery with less waste, less mess, and better adhesion—even under thermal processing.

How It Works

Big Taste, Tiny Particles

01

Particle-Size Optimization.

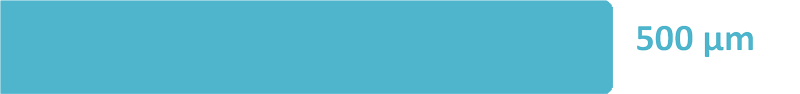

Reduces typical particle sizes from ~500 μm to ~5 μm, maximizing surface-area and flavor availability.

02

Oil-Phase Suspension.

Micro‑particles are stabilized in any food-grade oil or fat, preventing clumping, settling, and dusting.

03

Enhanced Flavor Delivery.

The combination of micro‑scale particles and lipid dispersion produces faster, stronger sensory release. Oil removes saliva from the tongue and allows optimal contact of the flavorant solid particle with the taste pores where it is rapidly dissolved in saliva in the pore to activate the nerves that carry the taste signals to the brain

Precision Flavor Engineering.

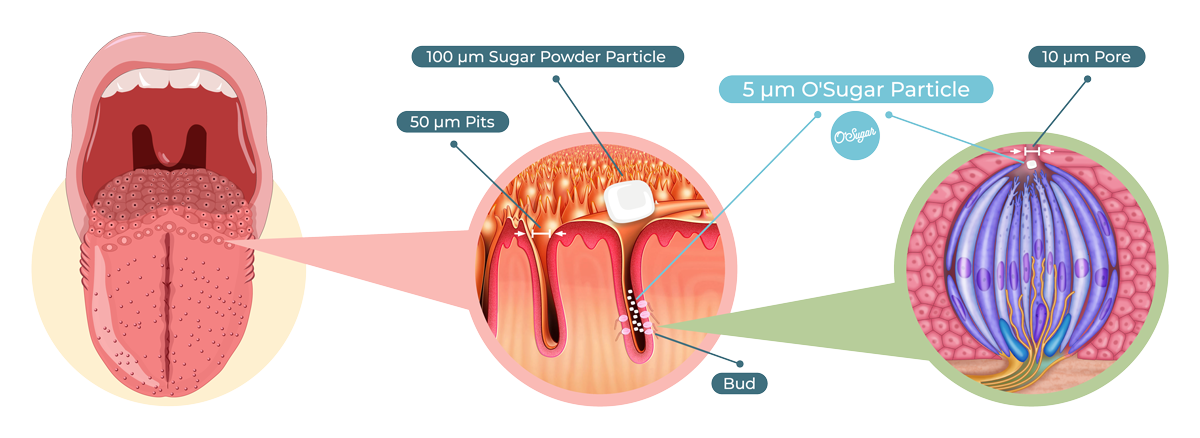

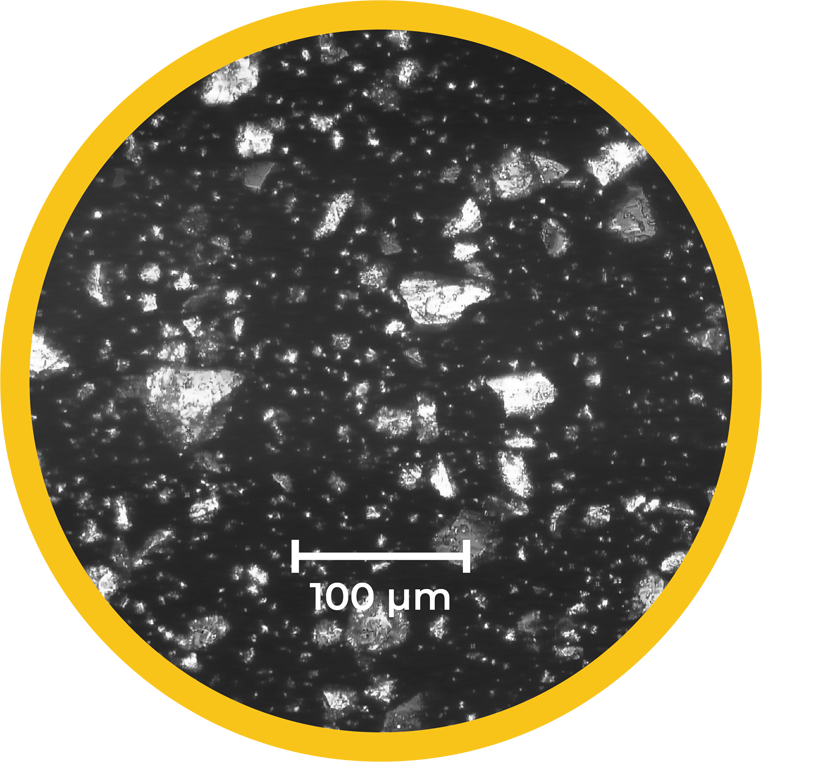

Taste happens at the micron scale.

Larger crystals, such as the ~20 μm particles found in conventional products like chocolate, are simply too big to access the pore; they must dissolve on the tongue’s surface, leading to slower response and significant flavor loss as material washes away with saliva. While each taste bud measures roughly 50–100 μm, the sensory pore where flavor is actually detected is only 1–10 μm wide.

O’Taste’s micromilled sugar and salt crystals — with a precise D50 of ~5 μm — are engineered to match this natural pore size. This allows each particle to enter the pore directly, dissolve exactly where taste is triggered, and activate a faster, stronger flavor signal.

With our oil-suspension system further reducing saliva interference, O’Taste ensures that more flavor reaches the sensory pore efficiently and fully — unlocking a cleaner and more impactful taste experience.

Increasing Surface Area As A Function Of

Reducing The Average Particles’ Size

Sugar Crystals

Median particle size

(D50) ~500um

Mild Sweetness

Sugar Powder

(+Stabilizers)

D50 ~100um

High Sweetness

Sugar in

O’Sugar

D50 ~5um

Very High Sweetness

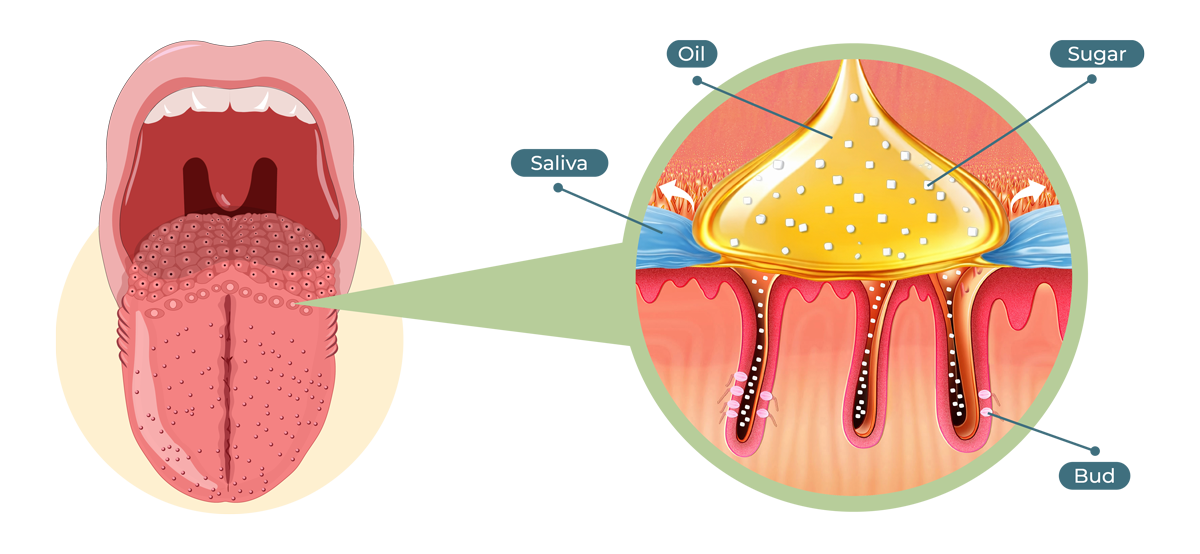

The Role of Oil

The tongue and pallet are normally covered with saliva that isolates the taste pit, the taste pore and the taste buds from solid flavorant particles. In order for sugar for example to reach the taste bud where flavor sensation occurs the sugar must be dissolved in a thick layer of water. Solution of large solids in water takes time and often saliva is swallowed before any significant mass of flavorant reaches the taste buds.

Oil is hydrophobic and removes water instantaneously from the pit and the pore thereby presenting micro sized flavorant particles directly to the micron thick layer in the taste bud where the sensory reaction occurs within milliseconds instead of seconds.

Immersing flavorants in oil allows significant reduction of the flavorant mass required for a given flavor sensation, thereby reducing the amount of sugar salt or spices required in foods.

As every chef knows adding oil or fat to spices adds strength and kick to the spice blend for exactly the same reason- faster and more efficient presentation of flavorant particles to the taste buds directly.

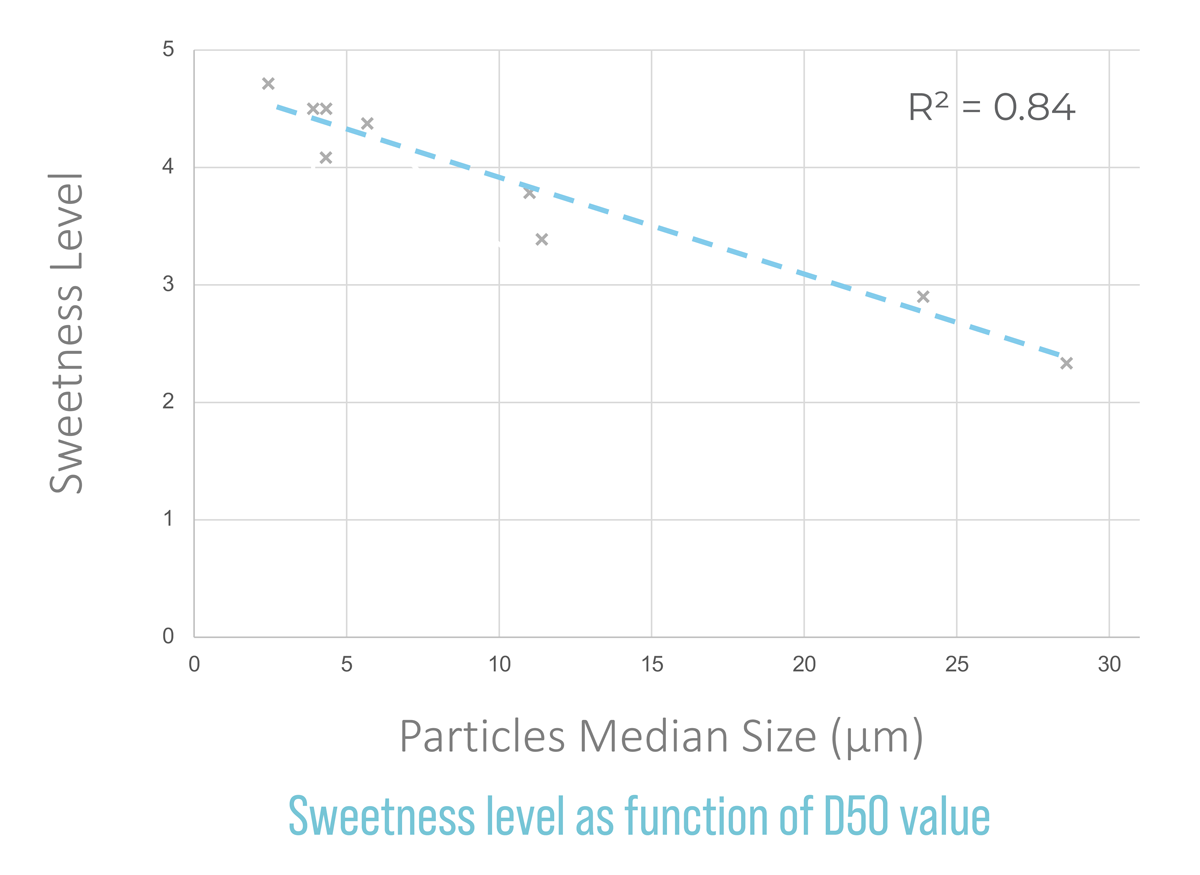

Sugar Particle Size vs. Sensory Strength

Standard Sugar Crystals — D50 ≈ 500 μm → Low sweetness

Powdered Sugar — D50 ≈ 50 μm → Medium sweetness

O’Sugar Micronized — D50 ≈ 5 μm → High sweetness via maximum surface area

Application Methods Across Manufacturing

O’Taste’s oil-suspended flavor systems can be easily incorporated into standard industrial processes. Common application methods include:

Spraying

Applies evenly across surface-area for snacks, popcorn, crackers, nuts.

Tumbling / Dry Coat Replacement

Eliminates dusting and improves adhesion.

Baking-in

Integrates flavor during dough/emulsion formation.

Enrobing

Suspended particles optimize chocolate, fat-based coating, nut butter layers.

Folding / Mixing into Fillings

Improved internal flavor distribution vs powders.

Injection or Inclusion

Concentrated flavor delivery into matrices with fat-phase.

Surface Coating

Stable lipid-phase distribution.

Thermal Processing

Suitable for fryer and oven environments.

Post-Bake / Post-Fry Application

Stronger flavor at lower payload.

The Health Benefits

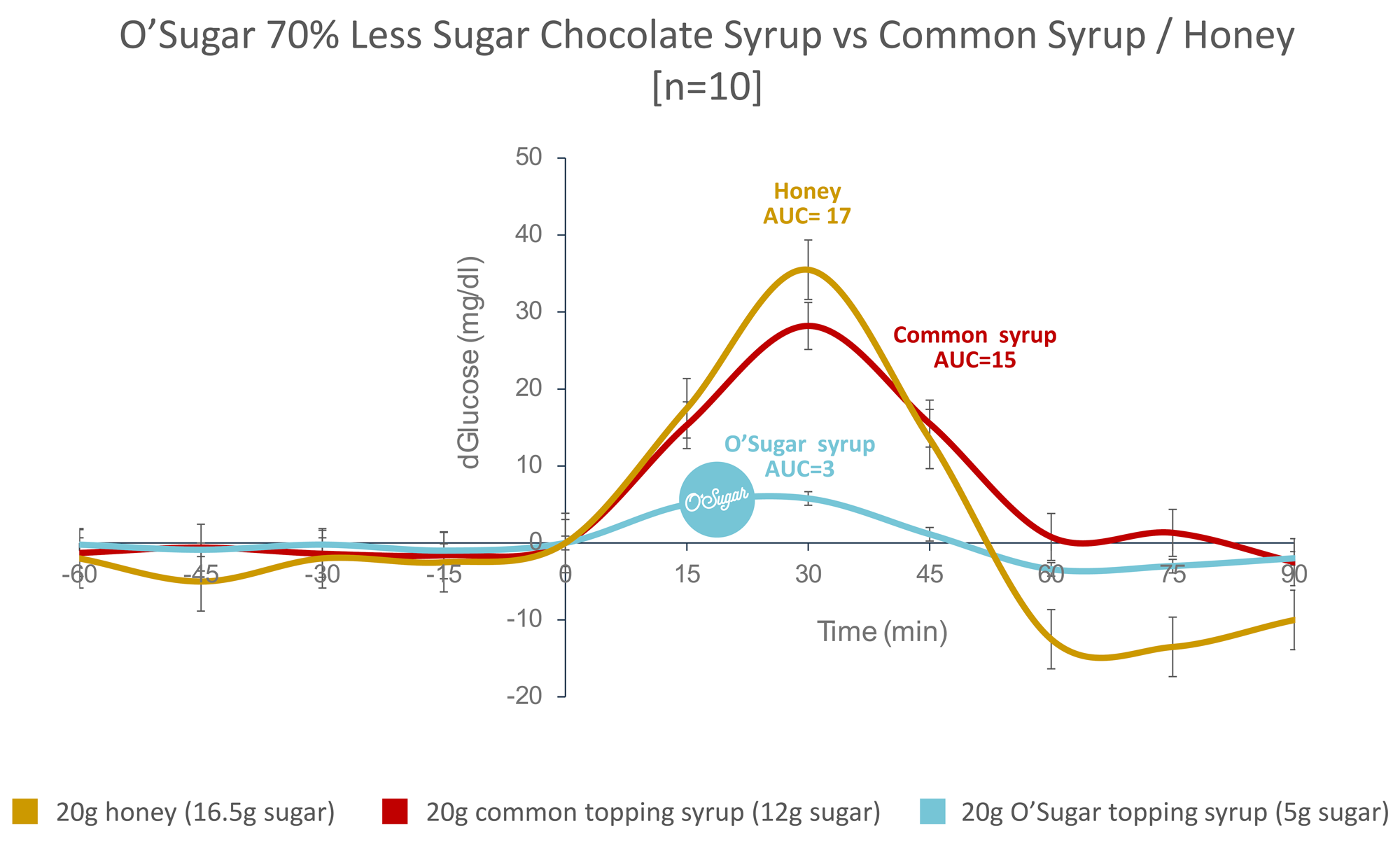

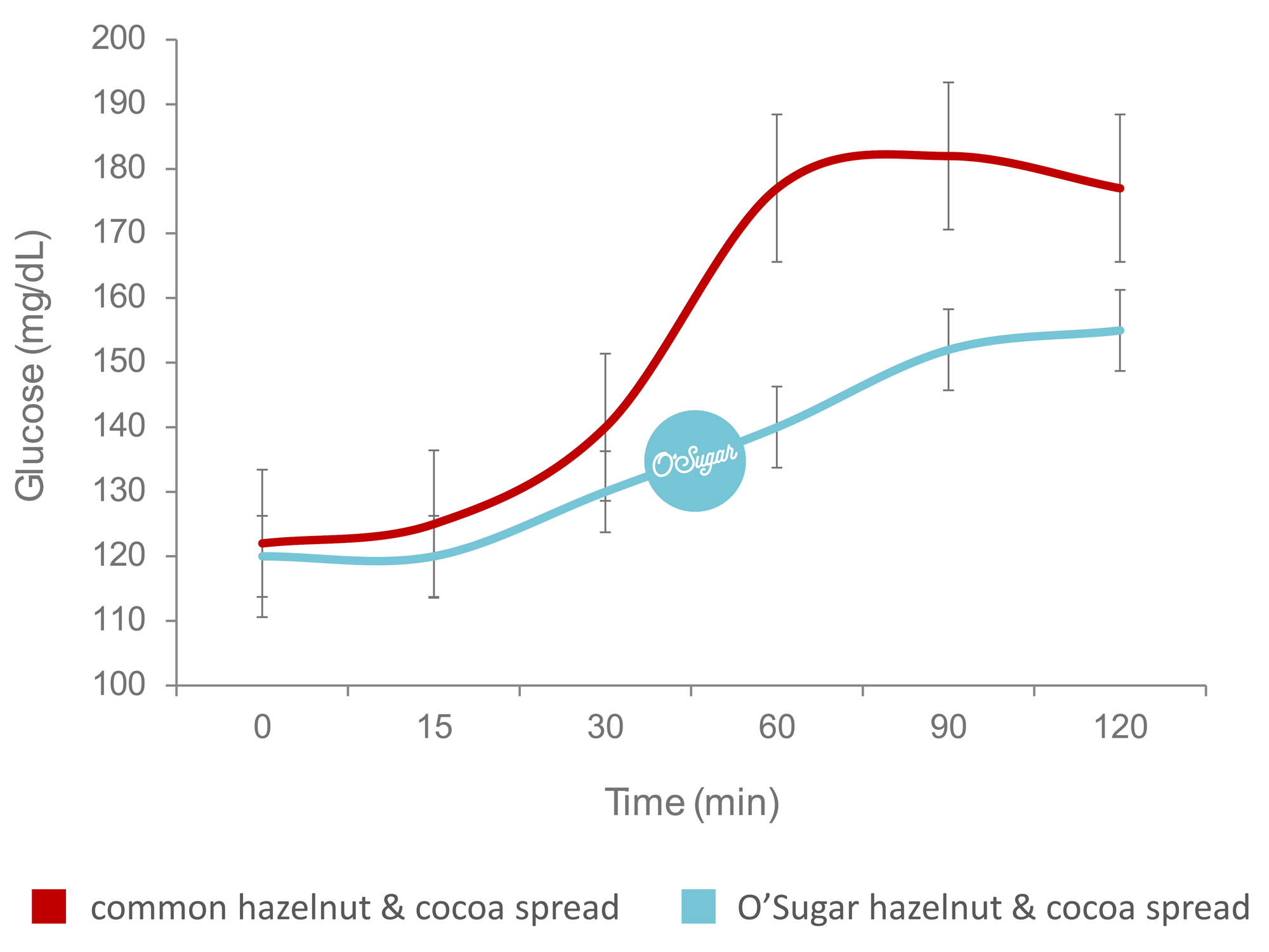

Postprandial Glucose Response to a Novel Low-Sucrose Chocolate Spread In Adults With Type 1 Diabetes: A Randomized, Double-Blinded, Cross-Over, Controlled Trial

Naama Fisch-Shvalb¹˒², Revital Nimri¹˒², Moshe Phillipi¹˒², Michal Yackobovitch-

Gavan¹˒³

“Comparisons of glycemic responses to a novel SR (Slow Release) food product compared to a commercially available equivalent showed that an 80% reduction in sucrose and 50% reduction in carbohydrate content resulted in a more favorable glycemic response, without compromising flavor. This new technology could significantly contribute to the ongoing effort to produce healthier sugar-reduced foods, both for people with diabetes, and for the general population. Further studies should be conducted to evaluate the impact of similar SR products on glycemia in different populations with diabetes and various meal types.”

Let’s make your food healthier, tastier, and smarter – together.

Whether you’re exploring new formulations or scaling production, our team can help.